Yokohama Rubber Fender Professional Manufacturer

Common dimensions and properties of Yokohama rubber fender

|

SIZE |

Initial pressure is 80 kPa Compression deformation 60% |

||

|

Diameter(mm) |

Length (mm) |

Reactionforce-kn |

Energyabsorb kn-m |

|

500 |

1000 |

87 |

9 |

|

600 |

1000 |

100 |

10 |

|

700 |

1500 |

182 |

28 |

|

1000 |

1500 |

241 |

40 |

|

1000 |

2000 |

340 |

54 |

|

1200 |

2000 |

392 |

69 |

|

1350 |

2500 |

563 |

100 |

|

1500 |

3000 |

763 |

174 |

|

1700 |

3000 |

842 |

192 |

|

2000 |

3500 |

1152 |

334 |

|

2000 |

4000 |

1591 |

386 |

|

2500 |

4000 |

1817 |

700 |

|

2500 |

5500 |

2655 |

882 |

|

3000 |

5000 |

2715 |

1080 |

|

3000 |

6000 |

3107 |

1311 |

|

3300 |

4500 |

2478 |

1642 |

|

3300 |

6000 |

3654 |

2340 |

|

3300 |

6500 |

3963 |

2534 |

Pneumatic rubber fender, yokohama fender instructions and maintenance precautions

1. The maximum deformation of Marine pneumatic fender in the use process is 60% (except for special ship type or special operation), and the use pressure is 50kpa-80kpa (the use pressure can be determined according to the user's ship type, tonnage size and near environment).

2. Pneumatic rubber fender should pay attention to avoid sharp objects in the use of puncture and scratch; And timely maintenance and maintenance, in general 5- 6 months for a pressure test.

3. Check regularly whether the ship's fender is puncted or scratched. The surface objects in contact with the fender shall not have sharp protruding hard objects to prevent puncturing the fender. When the fender is in use, the cable or chain or wire rope hanging the fender shall not be knotted.

4. When the Yokohama fender is not in use for a long time, it should be cleaned, dried in the sun, filled with appropriate amount of gas, and placed in a dry, cool and ventilated place.

5. The fender should be kept away from heat, and should not contact with acid, alkali, grease and organic solvent.

6. Do not pile up when not in use, do not pile up heavy objects on the fender.

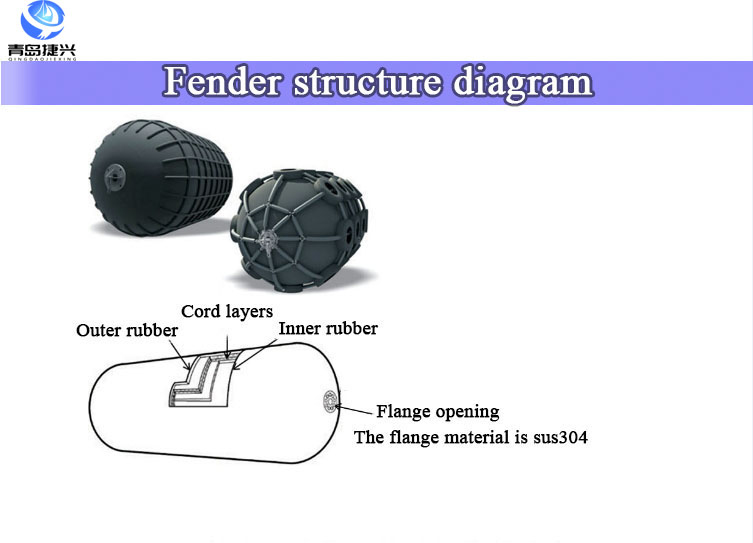

Yokohama fender structure diagram

Yokohama fender case display