Salvage Airbag is Used in Maritime Rescue Salvage

Marine Salvage Airbags

1. Marine and salvage airbags play a vital role in maritime salvage operations, including the rescue of stranded or sunken ships. Traditional lifting methods can be expensive and require large equipment, making them challenging for time-sensitive projects. By utilizing the innovative technology of airbags, salvage companies can complete the work quickly and efficiently.

2. The two primary methods of salvaging large sunken ships are buoy salvage and floating crane salvage. Current buoy technology consists of rigid, hard materials that offer high lifting capacity. However, rigid buoys can be negatively impacted by the underwater environment and require significant storage and transportation space, resulting in high costs.

3. Large floating cranes are the main tools for maritime salvage, but they are often limited by the lifting capacity of cranes and high transportation costs, which will lead to the increase of salvage costs.

4. The Marine salvage airbags made of flexible materials is flexible and multi-purpose, which can be folded or rolled into a cylinder for storage and transportation or diving, greatly improving the salvage ability of the salvage company. The salvage airbag can be inserted into the flooded cabin or fixed to the sunken ship deck, which has little force on the unit area of the hull and is beneficial to the safety of the hull. The influence of hydrological condition is relatively small when the salvage airbags dives, and the underwater operation efficiency is high.

5. Marine salvage airbag and Marine airbags can not only provide buoyancy for ship salvage, but also have great advantages in rescuing stranded ships. Through the launching airbags can be inserted into the bottom of the stranded ship, salvage airbag inflated can be jacked up the ship, in the action of dragging or after the thrust, the ship can be smoothly into the water.

Marine rubber airbag features

Using Marine airbag launching is a have independent intellectual property rights of innovative technology in China, is a very promising new process, it overcomes the small and medium-sized shipyard ship ever repaired the ability to slide, slide the restriction of traditional craft, because has the characteristics of less investment, quick effect, safe and reliable, get the welcome of the shipbuilding industry. Ship hoisting gasbag and scroll airbags as the main tool that will ship retainer on the balloon, from shipbuilding and ship repairing field into waters or migrate ashore from the water, using the Marine rubber airbag low inflation pressure, large bearing area and the characteristic of the still easy rolling after large deformation, use hoisting gasbag first ship lift from the block, on the scroll air bags, and then through the rolling traction and airbag, make the ship slowly slide into the water. Based on its innovative technology, Qingdao beierte Marine airbag designs and produces a new type of integral winding high strength Marine launching airbag, thus providing the most effective guarantee for the large ship's airbags launching technology.

Ship launching airbags is divided into: low pressure airbag, medium pressure airbag, high pressure airbag.

Marine airbags performance

|

Diameter |

Layer |

Working pressure |

Working height |

Guaranteed bearing capacity per unit length(T/M) |

|

D=1.0m |

6-8 |

0.18MPa-0.22MPa |

0.5m-0.8m |

≥13.7 |

|

D=1.2m |

6-8 |

0.17MPa-0.2MPa |

0.6m-1.0m |

≥16.34 |

|

D=1.5m |

6-8 |

0.16Mpa-0.18MPa |

0.7m-1.2m |

≥18 |

|

D=1.8m |

6-10 |

0.15MPa-0.18MPa |

0.7m-1.5m |

≥20 |

|

D=2.0m |

8-12 |

0.17MPa-0.2MPa |

0.9m-1.7m |

≥21.6 |

|

D=2.5m |

8-12 |

0.16MPa-0.19MPa |

1.0m-2.0m |

≥23 |

Dimensions and specifications of Marine airbags

|

Size |

Diameter |

1.0m,1.2m,1.5m,1.8m,2.0m,2.5m,2.8m,3.0m |

|

Effective Length |

8m, 10m,12m,15m,16m, 18m,20m,22m,24m,Etc. |

|

|

Layer |

4layer,5layer,6layer,8layer,10layer,12layer |

|

|

Remark: |

According to different launching requirements, different ship types and different ship weights, the slope ratio of berth is different, and the size of Marine airbag is different. If there are special requirements, can be customized. |

|

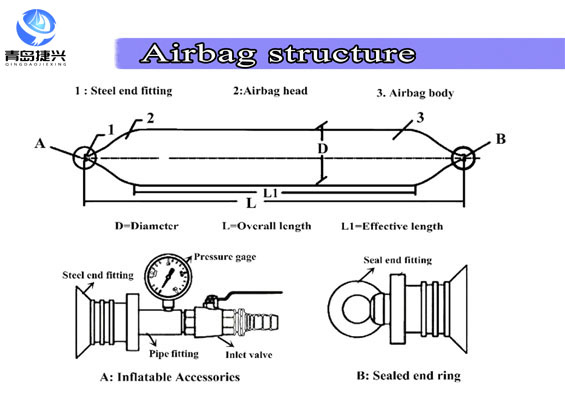

Schematic diagram of Marine airbag structure

Marine airbag fittings

Marine airbag case display